Quality

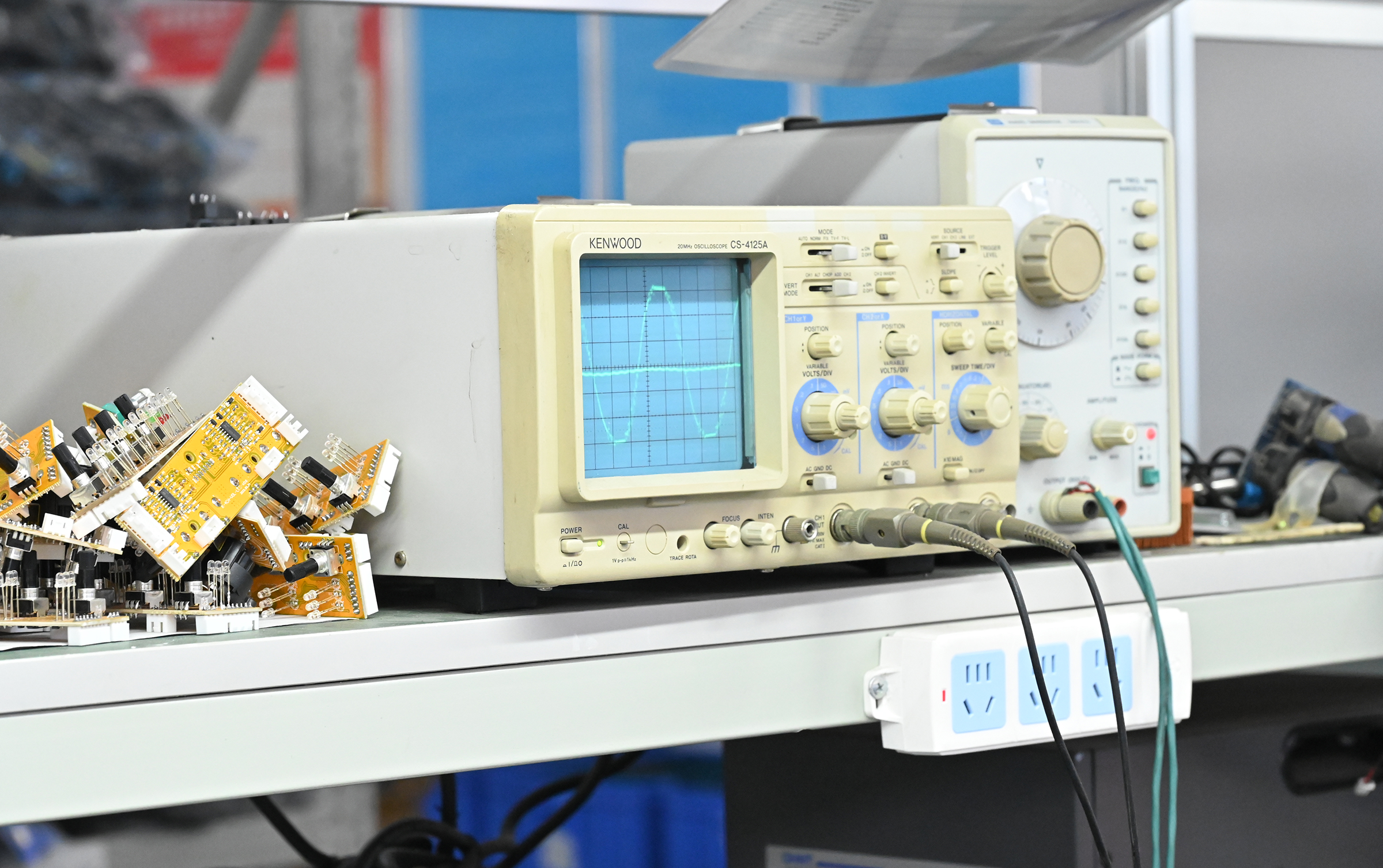

components test

Component quality inspection: It can determine the quality of resistors, capacitors, inductors, transformer and transistors

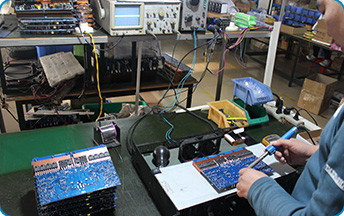

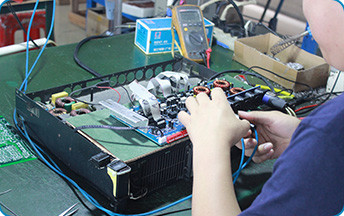

finished product test

Completely inspect and test the finished product before packing.

1- The oscilloscope can directly display the signal waveform and measure the instantaneous value of the signal.

2- Measure the operating voltage of the electronic circuit or component and compare it with the normal value to judge the fault

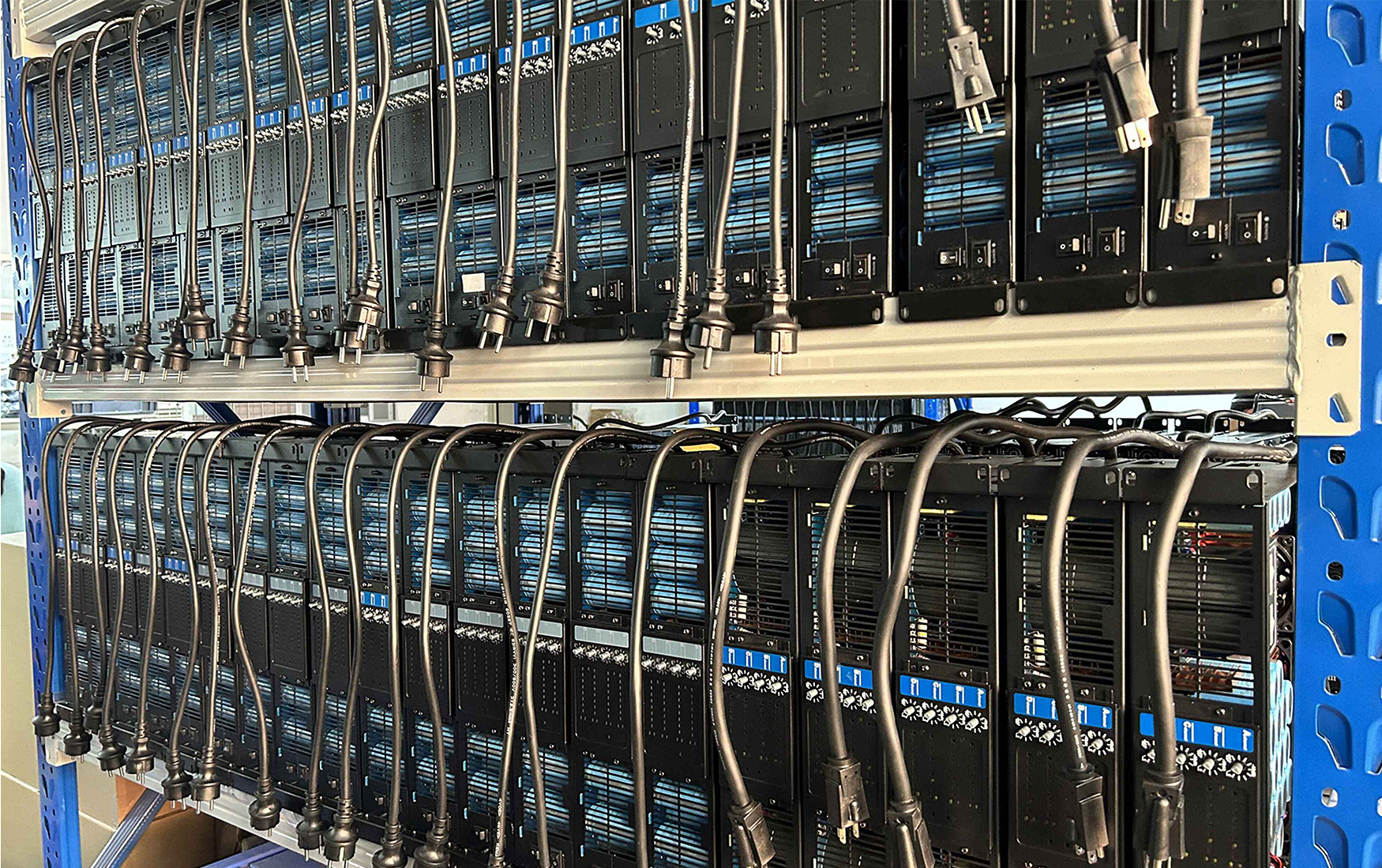

aging test

Aging test 8-10 hours before packing, ensure the quality of the product is qualified before packing.

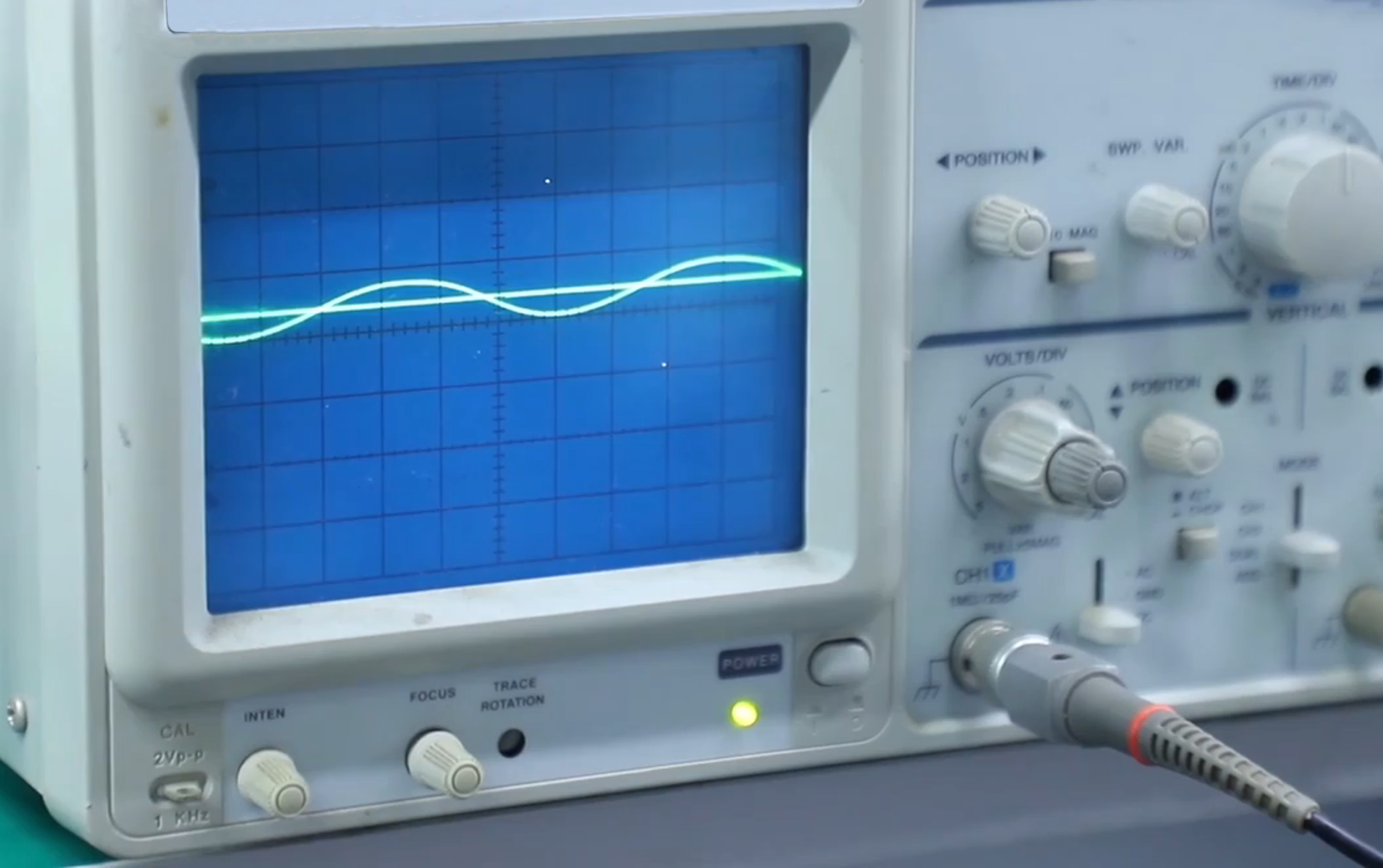

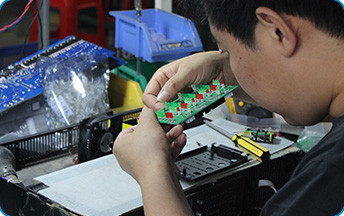

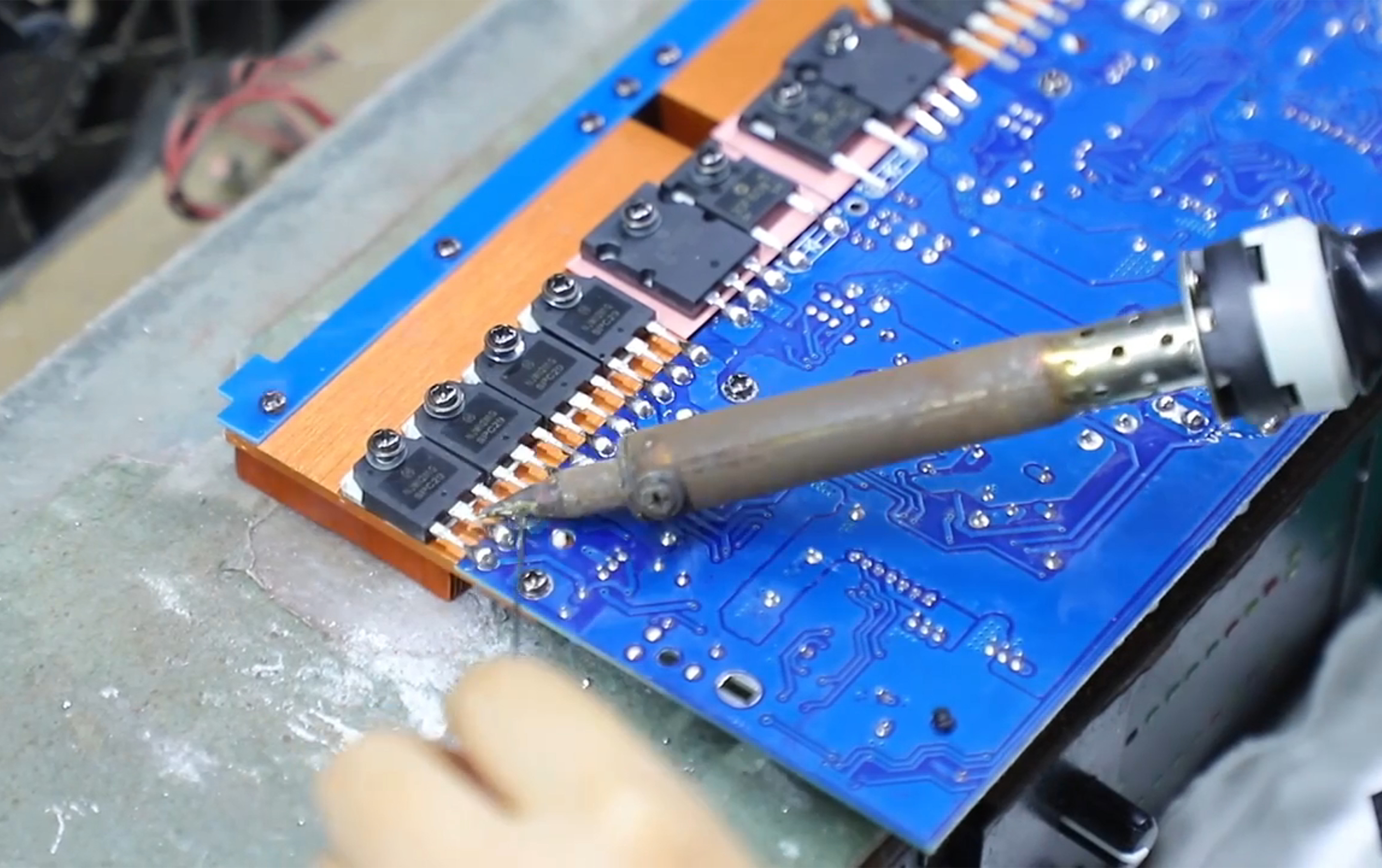

welding

The most important function of PCB soldering is to weld all the components together and let them play their roles. The solder joints and the protection component solder joints are not oxidized and dropped off.

product assembly

Assemble the components according to the specified technical requirements, after debugging and inspection to make them to be qualified products.

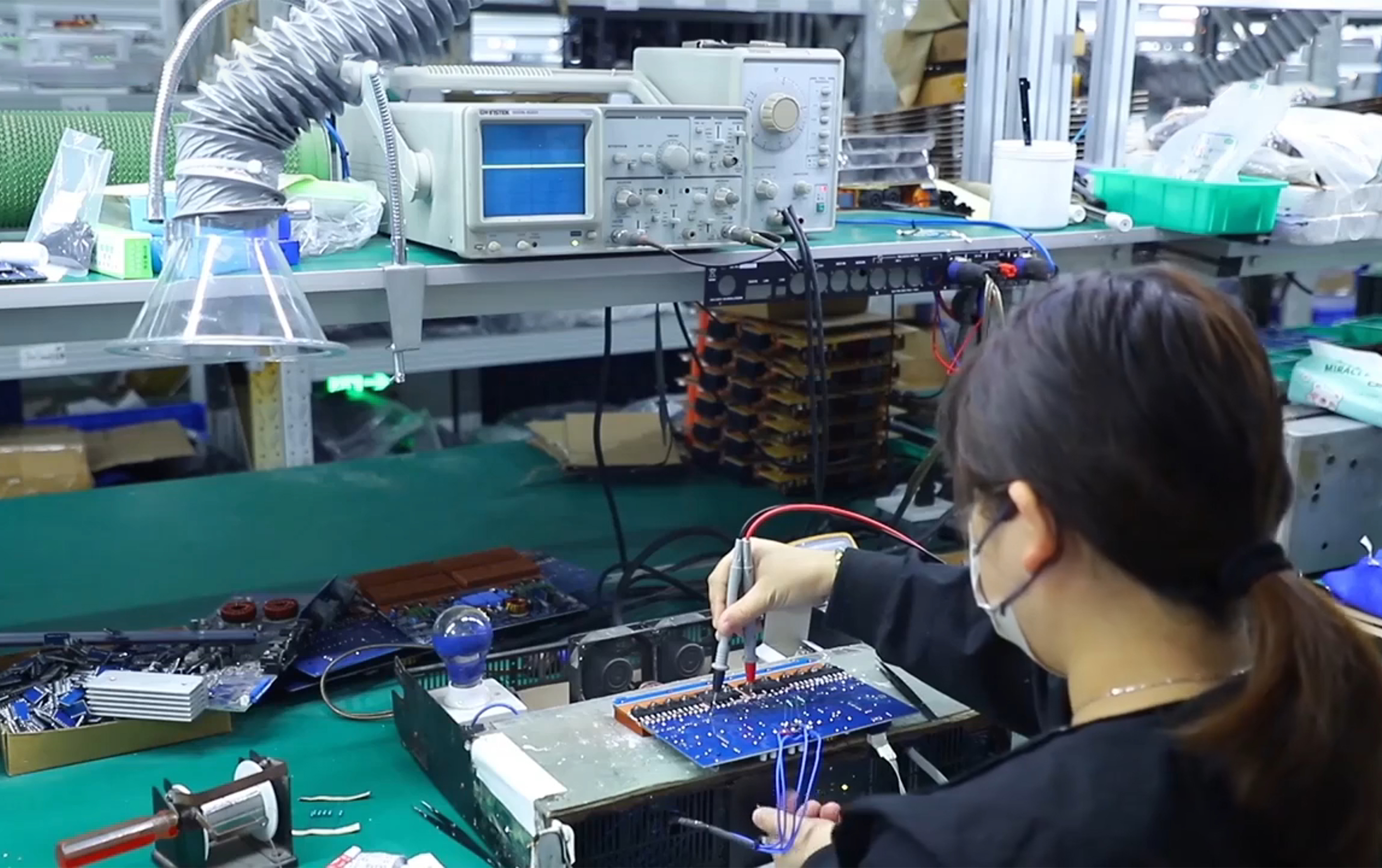

4- Test amplifier indicator light

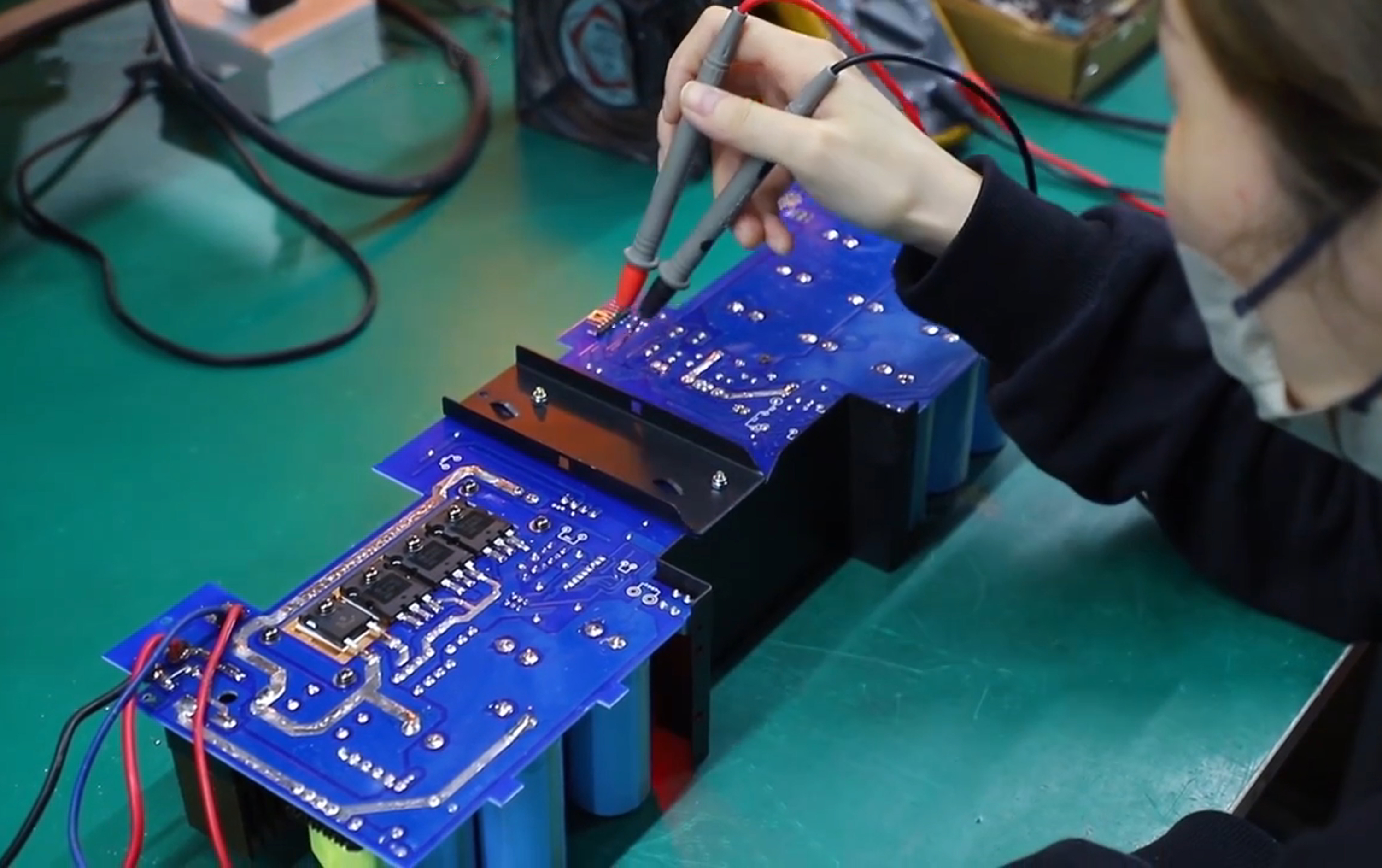

3- Test amplifier power supply board

Finished product

Finish all the tests and waitting for clean up.

components assembly

In accordance with the specified technical requirements, workers join several parts into components carefully.

semi finished product test

Ensure effective control of product quality.

2- Test output and input board

packing

Use a thick cardboard box and foam to make transportation without problems.

- Tel:

+86-020-86866877

+86-13342806188

- Email:

- sales7@sinbosen.com

- WhatsApp:

- 8613342806188

- Address:

- BUILDING A XINSHENG TECHNOLOGY PARK YINGBIN AVENUE WEST,XIUQUAN STREET HUADU DISTRICT GUANGZHOU GUANGDONG CHINA

- FP POWER AMPLIFIER

- DSP POWER AMPLIFIER

- 1U 4 ohms DIGITAL AMPLIFIER

- 1U 2 ohms DIGITAL AMPLIFIER

- 2 ohms Digital Amplifier V2.0

- Amplifier Module

- LINE ARRAY SPEAKER

- SUBWOOFER SPEAKER

- Point Source Speaker

- COAXIAL SPEAKER

- MONITOR SPEAKER

- COLUMN SPEAKER

- WIRELESS MICROPHONE SYSTEM

- WIRED MICROPHONE

- AUDIO PROCESSOR

- DRUM MICROPHONE KIT

- ANTENNA AMPLIFIER

- POWER DISTRIBUTOR

- HOT SELLING SET

- ACCESSORIES

sign up for the latest catalogue, new design and promotion